The fresh crayfish purchased from farmers are graded by three automated purchasing lines, and through five fine sorting capabilities, the crayfish are graded and screened; at the same time, unqualified crayfishes, weeds, etc. that are adulterated will be manually screened to check it out.

After grading and selection, the live crayfishes are deeply cleaned using an ultrasonic cleaning machine for 5 times to achieve the effect of two cleans and one white (clean crayfish belly, clean crayfish lines, and white meat).

After grading and selection, the live crayfishes are deeply cleaned using an ultrasonic cleaning machine for 5 times to achieve the effect of two cleans and one white (clean crayfish belly, clean crayfish lines, and white meat).

The crayfish is sterilized and matured through high-temperature cooking, which not only ensures the health of the crayfish meat, but also prevents the crayfish meat from losing moisture, and the taste is more guaranteed.

The steamed crayfish is rapidly cooled three times until the center temperature of the crayfish body reaches below 3°C, further ensuring the ultimate taste.

The steamed crayfish is rapidly cooled three times until the center temperature of the crayfish body reaches below 3°C, further ensuring the ultimate taste.

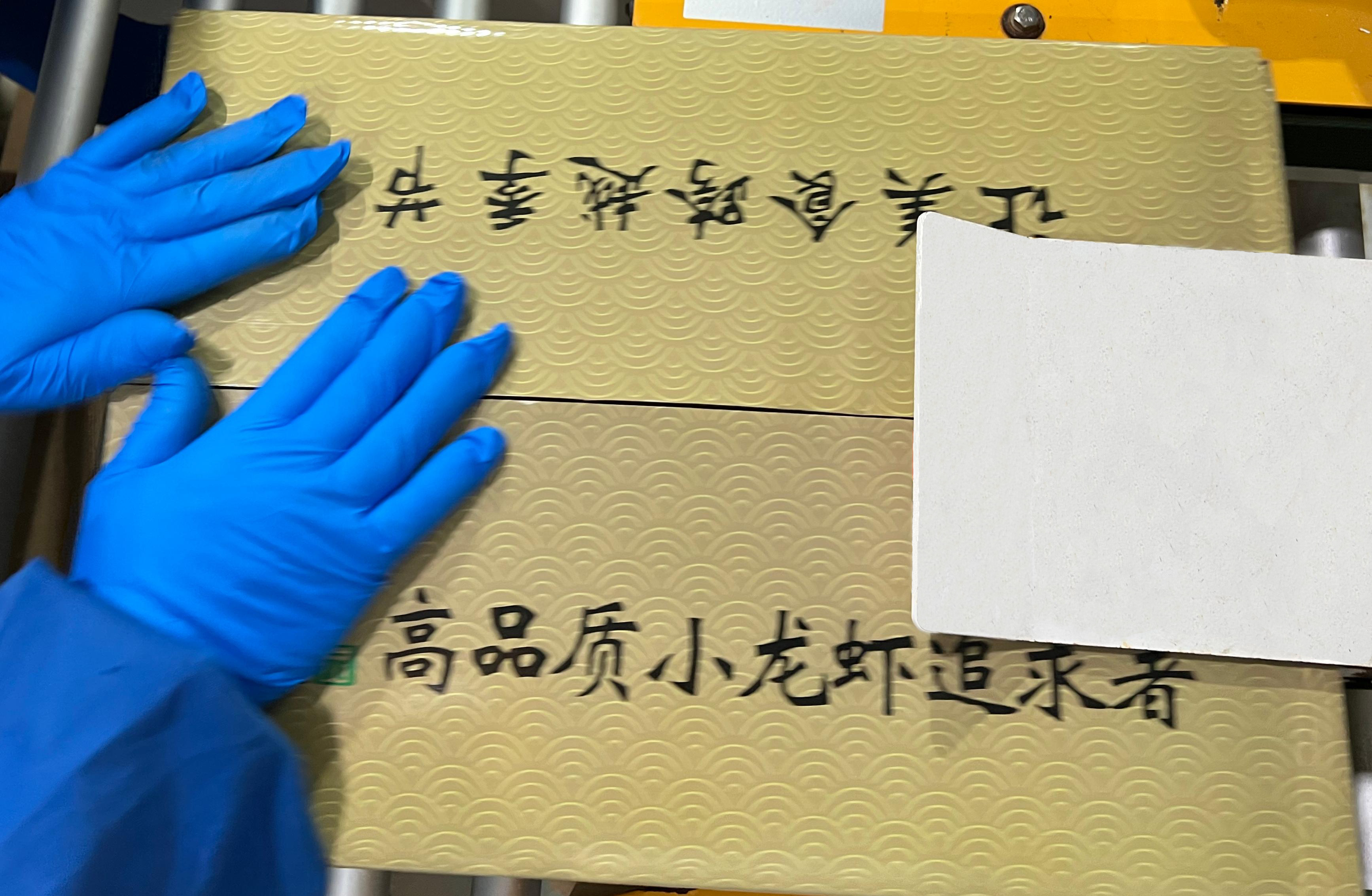

Purely manual sorting, every crayfish must be strictly controlled to avoid incomplete intelligence caused by machineization. Strictly implement process standards and grade products higher than industry standards to ensure the high quality of products to the greatest extent.

The quick-freezing plant has 13 large-scale leading quick-freezing equipment and 2 advanced ice-packing lines. After quick-frozen in liquid nitrogen at -196°C, the products are quickly frozen to lock in freshness, reducing intracellular water loss and maintaining the integrity and taste of the meat.

The quick-freezing plant has 13 large-scale leading quick-freezing equipment and 2 advanced ice-packing lines. After quick-frozen in liquid nitrogen at -196°C, the products are quickly frozen to lock in freshness, reducing intracellular water loss and maintaining the integrity and taste of the meat.

The cold storage is kept below -18°C all year round. The low temperature can not only refrigerate and preserve freshness, but also inhibit bacterial growth and maintain the original quality and nutritional content.